Automated Internal Defect Identification and Localization Based on Near-field SAR mmWave Imaging

A revolutionary compact mmWave SAR imaging system with automated defect detection framework achieving 91.7% average accuracy for fast, cost-effective non-destructive testing applications.

Abstract

Fast and cost-effective detection of internal defects is essential for structural integrity inspection in various applications in manufacturing, construction, and aerospace. Current internal non-destructive testing (NDT) methods, including computed tomography, are costly, time-consuming and constrained by object size. The lightweight and affordable millimeter wave (mmWave) radar has demonstrated the capability of detecting objects beneath surfaces or obstacles.

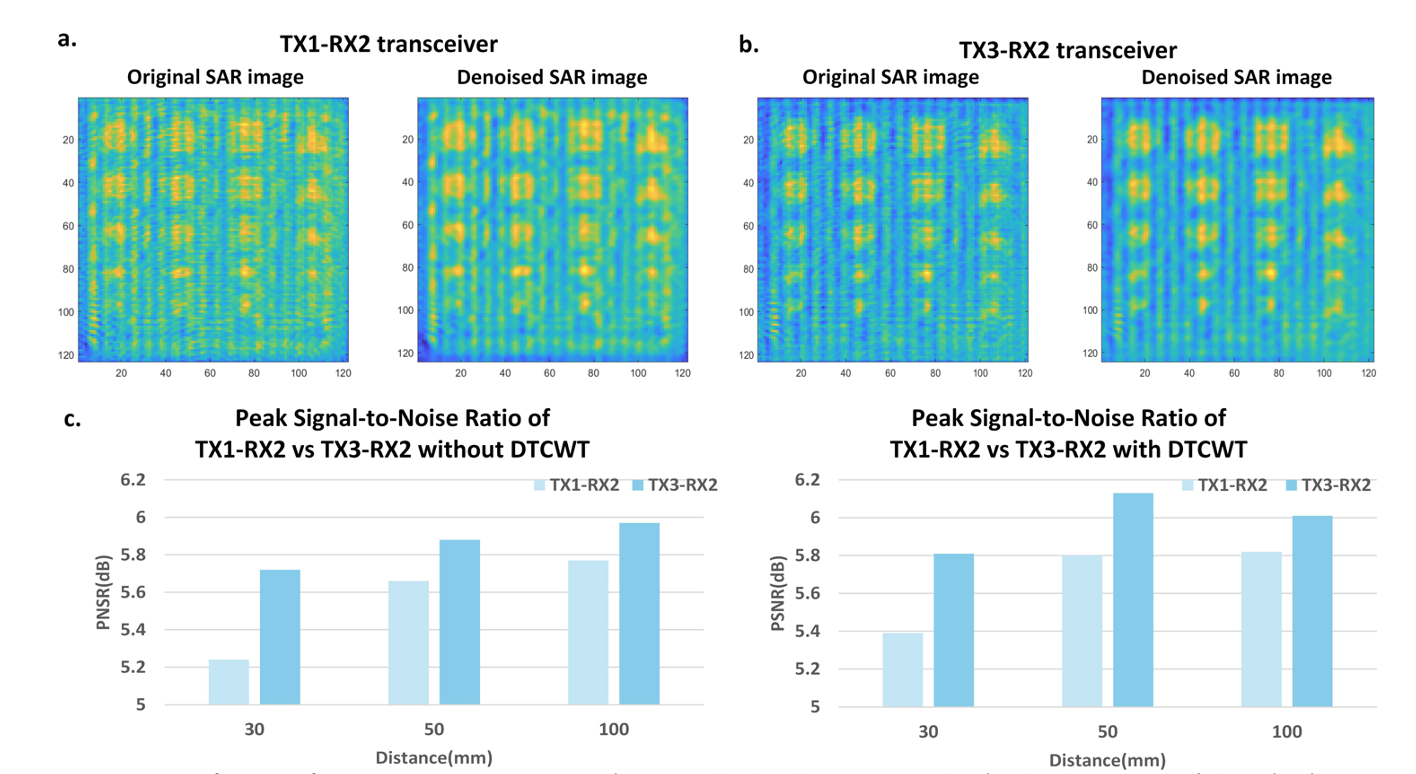

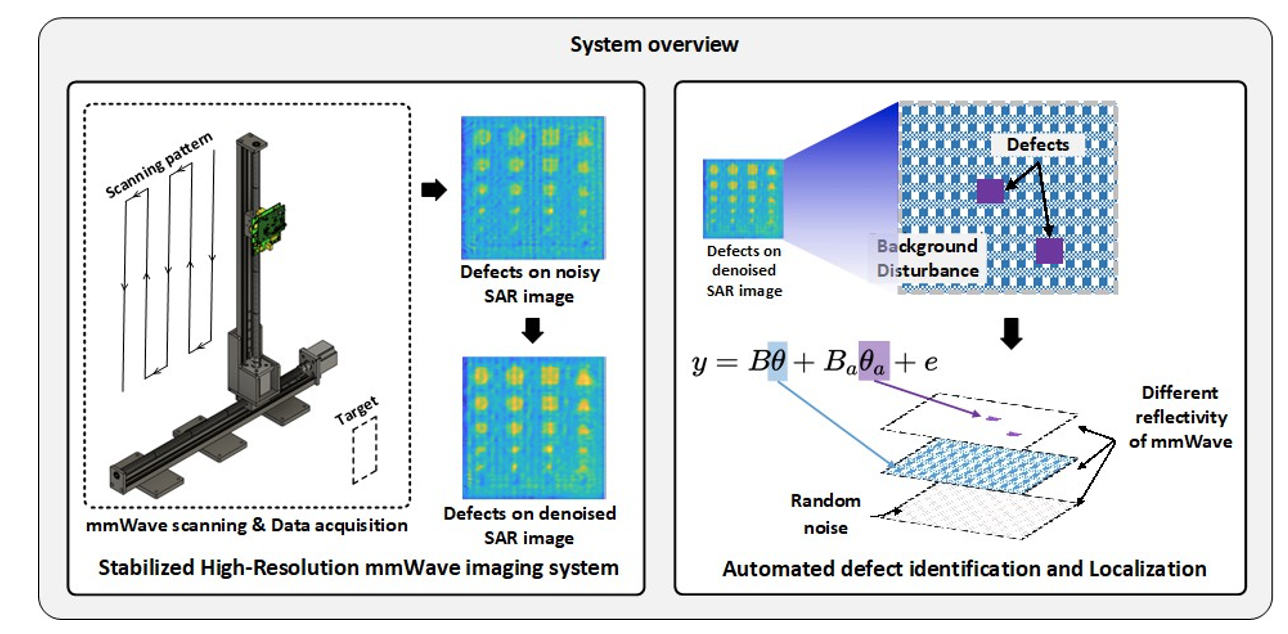

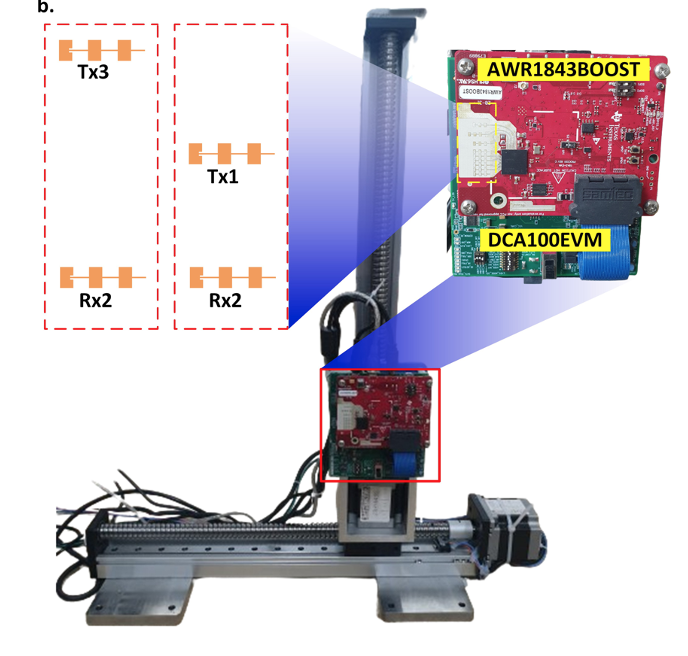

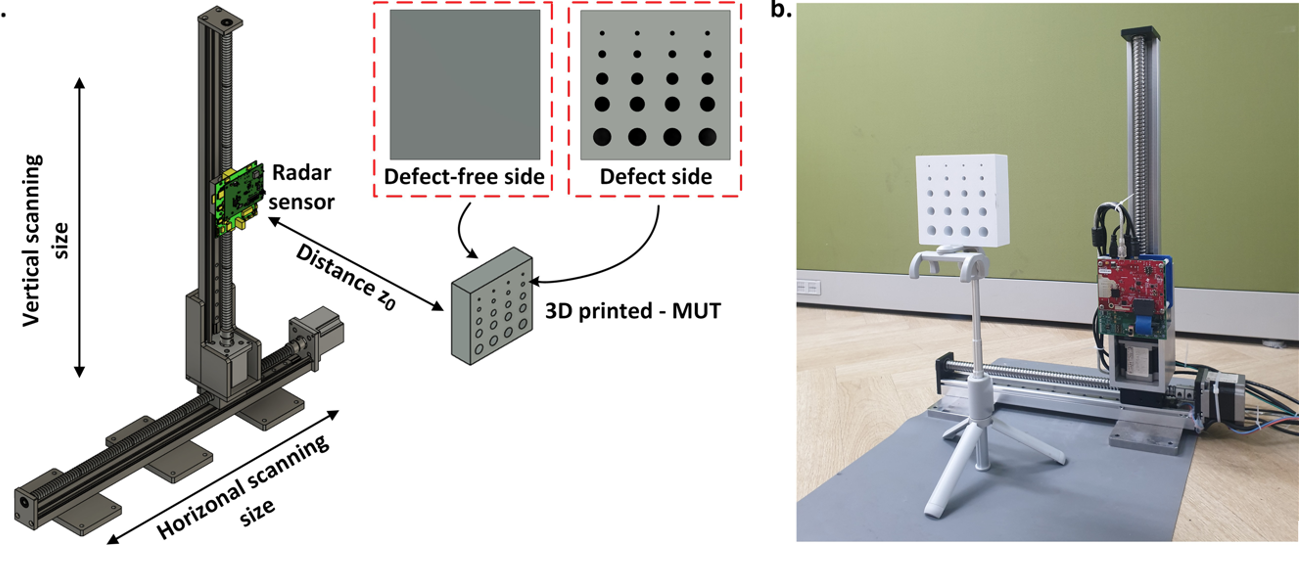

This work establishes a robust and automated internal defect detection framework employing a compact mmWave radar system on a stable rail-based scanning mechanism, generating high-resolution near-field SAR images with an enhanced signal-to-noise ratio through denoising. For fast and accurate detection, an automated defect localization algorithm is developed that models and separates internal defects from disturbances introduced by the scanning mechanism.

The proposed method achieved an average accuracy of 91.7%, outperforming existing methods, making it easily integrable into larger scanning systems and adaptable to various object sizes.

Advanced Image Decomposition Algorithm

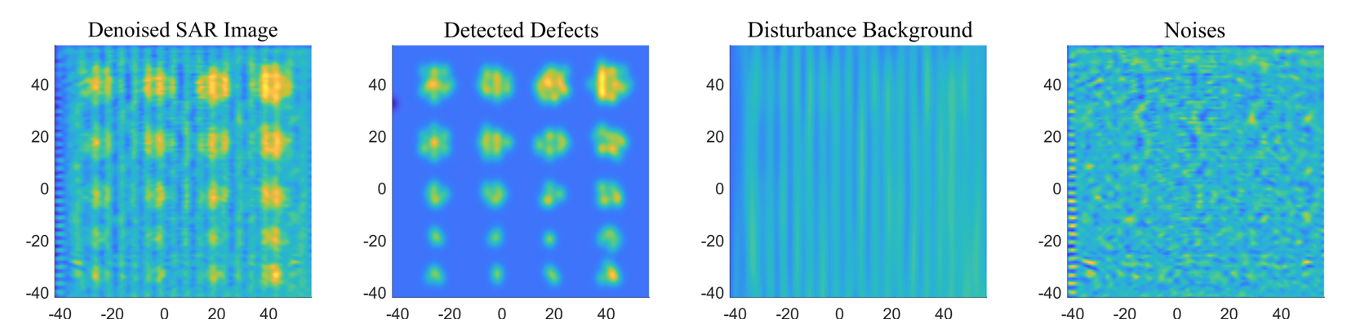

Process-informed smooth-sparse decomposition (PISSD) methodology for automated defect localization

Comprehensive image decomposition showing denoised SAR image, detected defects, disturbance background, and noise components - enabling precise defect identification even in challenging scanning conditions.

Breakthrough Performance Results

Revolutionary improvements in non-destructive testing accuracy and efficiency

Key Innovations & Industrial Impact

This research presents a paradigm shift in non-destructive testing technology by introducing a compact, cost-effective mmWave SAR imaging system that dramatically reduces inspection time and costs while maintaining superior accuracy. The integration of automotive-grade mmWave sensors with advanced image processing algorithms creates unprecedented opportunities for real-time quality control in manufacturing environments.

The automated defect detection framework addresses critical industry challenges including operator-induced false identifications, time-consuming manual inspections, and the need for expensive, bulky equipment. By achieving 91.7% average accuracy across multiple test scenarios, this system establishes new benchmarks for internal defect detection in aerospace, construction, and manufacturing applications.

The modular design enables seamless integration into existing production lines, while the automated processing significantly reduces the need for specialized operators, making advanced NDT technology accessible to a broader range of industrial applications and opening new possibilities for in-situ structural health monitoring.